Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

The manufacturing world is evolving rapidly, with new technologies emerging that promise to revolutionize the way products are made. One such technology is rapid tooling with 3D printing, which allows businesses to create high-precision tools and prototypes quickly and cost-effectively. But how does this process work, and what makes it so effective?

In this article, we’ll take a deep dive into the concept of rapid tooling using 3D printing, explaining how it functions, the advantages it offers, and the industries that benefit from it. By the end of this post, you'll have a clear understanding of how rapid tooling with 3D printing works and why it’s a game-changer for manufacturers looking to stay competitive.

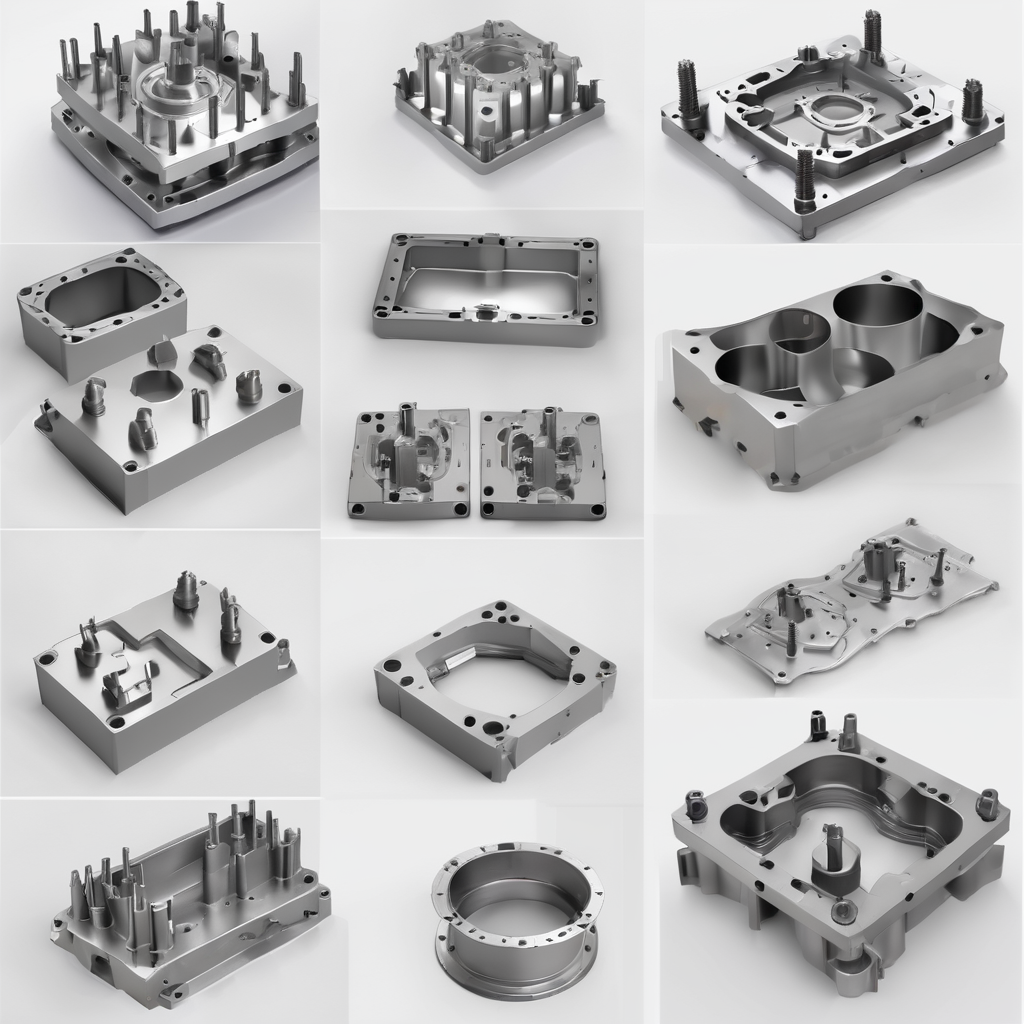

Rapid tooling refers to the creation of production tools, such as molds, dies, and fixtures, at a faster pace than traditional methods. Unlike conventional tooling, which can take weeks or months to develop, rapid tooling is designed to reduce lead times by utilizing advanced technologies, such as 3D printing, to manufacture tools quickly.

With rapid tooling, companies can produce prototypes, test designs, and create low-volume production tools without the time and cost constraints that typically come with traditional tooling methods. It’s a powerful tool for industries that need to move quickly from concept to production.

3D printing plays a critical role in rapid tooling. By using additive manufacturing techniques, such as fused deposition modeling (FDM) or stereolithography (SLA), manufacturers can directly print tool components with high precision, cutting down the need for traditional manufacturing processes. This makes it possible to produce complex shapes and geometries that are difficult or impossible to achieve with conventional methods.

Moreover, 3D printing allows for more efficient and flexible design changes, enabling faster iterations and reduced risk of error. This capability makes it ideal for industries like automotive, aerospace, and medical device manufacturing, where speed and precision are essential.

The first step in the process of rapid tooling with 3D printing is designing the tool or part using computer-aided design (CAD) software. The design is typically created by a team of engineers who ensure that the tool will meet functional specifications while also being optimized for 3D printing. The flexibility of CAD allows for the integration of intricate features that would be challenging to create using traditional methods.

Once the design is finalized, it is converted into a 3D model format, typically STL (stereolithography), that is compatible with 3D printing. This file is sliced into thin layers, and the 3D printer uses this information to create the object layer by layer.

3D printers use a range of materials to print the tool, depending on the requirements of the project. For rapid tooling, common materials include thermoplastics, metal-filled filaments, or even resins. The printer builds up the material layer by layer to create the part, with the precision of each layer controlled by the 3D printer's resolution capabilities.

Once the tool has been printed, it usually undergoes post-processing steps, such as curing, polishing, or adding coatings. These processes help to improve the finish and strength of the tool, making it suitable for real-world applications.

After the tool is finished, it is tested to ensure that it meets the functional requirements. If adjustments are needed, the digital design can be modified and reprinted quickly, allowing for fast iterations and reducing the risk of costly mistakes. This iterative approach is a huge advantage of using 3D printing for rapid tooling, as it speeds up the prototyping phase and allows for continuous improvement.

One of the primary advantages of rapid tooling with 3D printing is its speed. Traditional tooling methods can take weeks to complete, while 3D printing significantly reduces lead times by creating prototypes and tools in a fraction of the time. This faster turnaround allows manufacturers to move quickly from design to production, improving overall efficiency.

Traditional tooling methods often involve costly processes like machining, casting, and welding, which require significant labor and material costs. With 3D printing, many of these costs are reduced or eliminated, making rapid tooling a more affordable option for producing low-volume or prototype tools.

3D printing allows for the creation of intricate, complex geometries that would be nearly impossible to achieve with traditional manufacturing processes. Whether it’s a tool with intricate cooling channels, internal features, or unique shapes, 3D printing can produce highly detailed and precise parts in one go.

Since 3D printing uses digital files, making design changes is relatively easy. Designers can tweak the CAD model, update the file, and print a new version without the need to create entirely new tooling. This flexibility allows for rapid design iteration and modification, which is particularly useful when testing different concepts or adapting tools for different production runs.

Traditional manufacturing processes often generate a significant amount of waste material, especially in processes like machining or casting. In contrast, 3D printing is an additive process, meaning that material is only added where it’s needed, minimizing waste and making it a more sustainable option for tooling production.

The automotive sector benefits greatly from rapid tooling with 3D printing, especially in the development of prototypes for new vehicle models. 3D printing allows for quick turnaround on test parts, as well as low-volume production of tooling for specific vehicle components. This results in faster development cycles and more cost-effective production methods.

The aerospace industry requires high-precision, lightweight components, and rapid tooling with 3D printing is ideal for this purpose. The ability to create complex parts with reduced weight and high accuracy helps improve the performance and safety of aircraft components. Additionally, the quick turnaround of prototypes and tools allows aerospace companies to test and refine their designs quickly.

For the medical industry, precision is key. With rapid tooling, medical device manufacturers can produce molds and tools for custom implants, surgical instruments, and prosthetics with a high degree of accuracy. 3D printing also allows for fast iteration of designs, ensuring that medical devices meet stringent regulatory standards while being produced efficiently.

Consumer electronics manufacturers use rapid tooling to create prototypes and production tools for everything from smartphone cases to wearables. The ability to quickly prototype designs, test them for functionality, and create tools for low-volume production makes rapid tooling with 3D printing a go-to solution in the electronics industry.

The industrial sector benefits from rapid tooling by enabling manufacturers to produce parts and tools on-demand, without the need for long lead times. This flexibility is especially valuable in industries such as machinery, industrial equipment, and heavy manufacturing, where parts often need to be customized or produced in low volumes.

Rapid tooling with 3D printing has revolutionized how manufacturers approach the production of prototypes, molds, and tooling. The speed, cost-effectiveness, and precision it offers make it a powerful tool for industries ranging from automotive to aerospace, medical devices, and beyond. By embracing rapid tooling, companies can streamline their development processes, reduce waste, and stay ahead in an increasingly competitive market.

A: 3D printing allows for faster production of tools, precise geometries, and quick iterations, making it ideal for rapid tooling. It significantly reduces lead times and costs compared to traditional tooling methods.

A: While rapid tooling is excellent for low-volume and prototype production, it can also be used to create tools for mass production, especially when speed and flexibility are required.

A: Common materials for 3D printing in rapid tooling include thermoplastics, metal-filled filaments, resins, and even metal powders for metal 3D printing processes.

A: Industries such as automotive, aerospace, medical devices, consumer electronics, and industrial manufacturing benefit greatly from rapid tooling with 3D printing due to its speed, cost-effectiveness, and precision.