Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

Have you ever wondered how manufacturers quickly produce prototypes or create tooling for mass production without long wait times or huge costs? The answer lies in rapid tooling. In today's competitive market, speed and precision are essential, and rapid tooling has emerged as a game-changer in the manufacturing world.

In this article, we'll explore what rapid tooling is, how it works, and why it's becoming the go-to method for companies looking to expedite their production process. We'll dive into its applications, advantages, and real-world uses, helping you understand how rapid tooling can benefit your production cycles. By the end, you'll have a clear understanding of this critical technology and how it can streamline your manufacturing efforts.

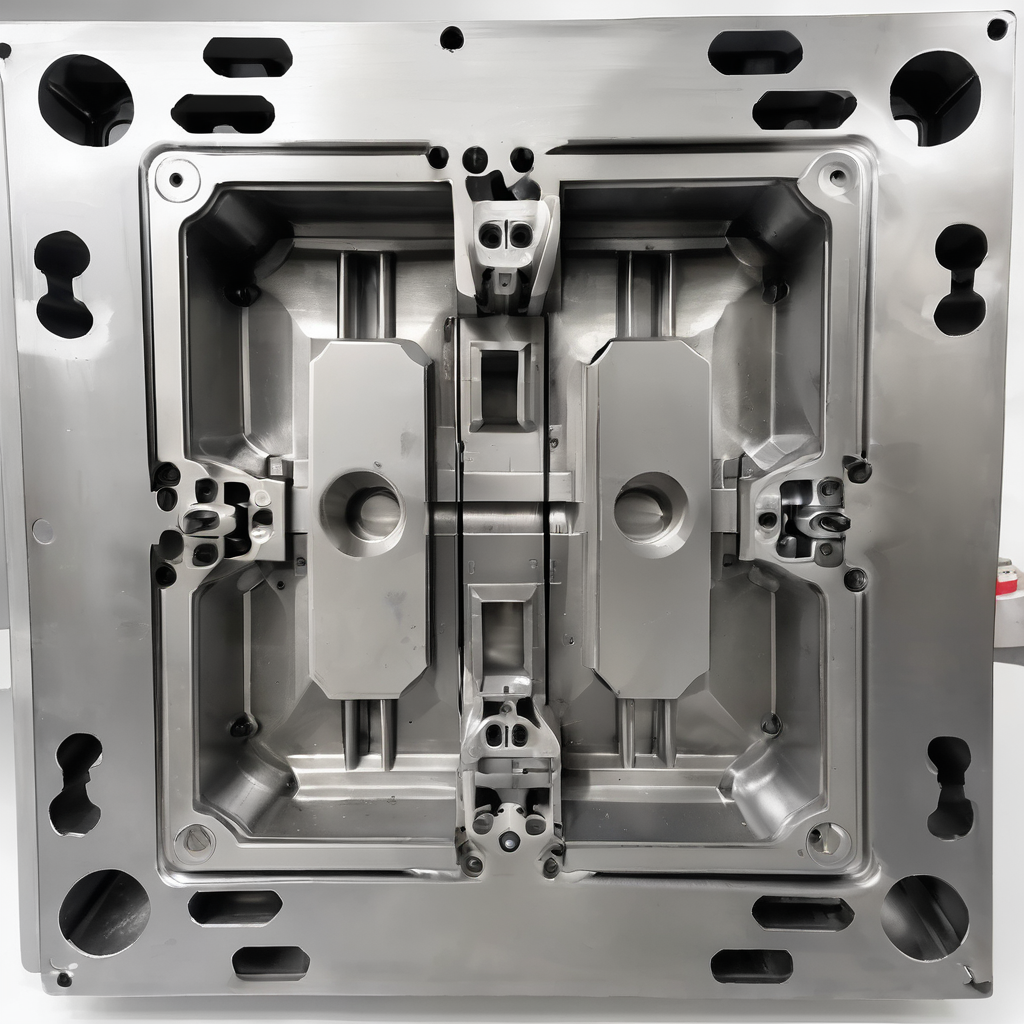

Rapid tooling refers to the process of creating tools (such as molds, dies, or prototypes) quickly using advanced manufacturing techniques like 3D printing, additive manufacturing, or advanced CNC machining. Unlike traditional tooling methods, which can take weeks or even months to design and manufacture, rapid tooling significantly reduces lead times, offering fast turnaround for creating functional prototypes and production tools.

This method is ideal for situations where speed is of the essence—such as when companies need to test designs, refine processes, or move to full-scale production quickly. It's a solution designed for speed, flexibility, and precision, all while keeping costs in check.

1. Digital Design: Rapid tooling typically starts with a digital 3D model, which is designed using computer-aided design (CAD) software. This model acts as the blueprint for the tool or part.

2. Additive Manufacturing: Techniques like 3D printing or stereolithography (SLA) are often used to create the tool or mold quickly. These methods allow for complex geometries that would be challenging to achieve with traditional manufacturing methods.

3. Machining and Casting: After the digital design is made, it can be translated into physical tools via methods like CNC machining or injection molding. These techniques enable companies to create functional parts directly from the rapid tooling molds.

One of the primary uses of rapid tooling is to create prototypes for testing and validation. Traditional prototyping methods can be expensive and slow, but rapid tooling allows designers to test their concepts much faster. Prototypes produced through rapid tooling can be functional, giving teams an accurate representation of how a final product will perform under real-world conditions.

● Benefits: Speed and cost-effectiveness in producing prototypes for testing and design iterations.

● Use Cases: Automotive prototypes, electronic enclosures, medical device testing, etc.

Rapid tooling is also ideal for low-volume production runs. In industries where mass production isn't required, but functional parts are still needed, rapid tooling allows companies to produce parts at a fraction of the cost and time of traditional manufacturing. It's an excellent option for parts that are not in high demand or for pilot runs before scaling up.

● Benefits: Cost-efficient for producing small quantities of parts.

● Use Cases: Spare parts, limited-edition products, customized industrial components.

In addition to prototypes, rapid tooling is used to create tools, such as molds and dies, for actual production. These tools are used for processes like injection molding, die-casting, and metal forming. Rapid tooling allows companies to produce these tools quickly and cost-effectively, enabling faster product launches.

● Benefits: Fast creation of molds, tools, and dies that are used for mass production.

● Use Cases: Plastic injection molds, casting molds, tooling for assembly lines.

One of the standout features of rapid tooling is its ability to create intricate geometries that are impossible to achieve with traditional tooling methods. Whether it's undercuts, thin walls, or complex shapes, rapid tooling provides the flexibility to handle complex designs that require precision.

● Benefits: Ideal for intricate designs that traditional tooling cannot achieve.

● Use Cases: Aerospace components, medical devices, automotive parts.

Rapid tooling is also valuable for industries that require a high degree of customization. Whether you're producing customized parts for specific applications or need on-demand production, rapid tooling allows for flexibility in design and quick adjustments to meet changing requirements.

● Benefits: Quick adaptation to design changes and custom orders.

● Use Cases: Customized medical implants, specialized automotive parts, or consumer goods.

One of the most significant advantages of rapid tooling is its speed. Traditional tooling can take weeks or even months to create, while rapid tooling can reduce this time to just days or weeks, allowing for faster prototyping and production.

Rapid tooling allows manufacturers to produce tools and prototypes without the high costs associated with traditional methods. Since many rapid tooling processes use digital designs and additive manufacturing, the setup and tooling costs are much lower, making it an attractive option for businesses on a budget.

With rapid tooling, design changes can be made easily and quickly, without the need to rework the entire tool. This flexibility is crucial in industries where designs often evolve during the development process.

Rapid tooling processes, such as 3D printing and CNC machining, offer high levels of precision, allowing for high-quality parts and tools. This ensures that the end product meets exact specifications and functional requirements.

Rapid tooling can be used to both create prototypes and produce the final product's tools, making it a one-stop solution for many manufacturing needs. This streamlines the process and helps businesses save time and resources.

1. Initial Design: A 3D CAD model of the part or tool is created using design software. This digital design is the foundation of the rapid tooling process.

2. Tool Production: Using rapid manufacturing methods like 3D printing, laser sintering, or CNC machining, the mold or tooling is created. This stage can take anywhere from a few hours to a few days, depending on the complexity of the design.

3. Part Production: Once the tooling is ready, parts are produced by processes such as injection molding, casting, or compression molding. The quick turnaround times mean that parts can be produced rapidly for testing or low-volume production runs.

4. Testing and Refinement: Prototypes produced using rapid tooling can undergo testing, and design adjustments can be made quickly, further speeding up the production cycle.

In the automotive industry, rapid tooling is crucial for producing prototype parts, testing new designs, and creating molds for low-volume production runs. Rapid tooling enables manufacturers to bring new models to market faster, saving time and reducing development costs.

The aerospace industry relies on rapid tooling for creating precision parts and components with complex geometries. The lightweight materials and durability provided by rapid tooling are essential for high-performance aerospace parts.

For consumer products, especially in the electronics and appliance industries, rapid tooling allows manufacturers to quickly test new designs and bring products to market more efficiently. It also aids in creating custom molds for specific product lines.

The medical device industry benefits from rapid tooling's ability to produce high-precision parts that meet stringent regulatory standards. Rapid tooling is also useful for creating prototypes of devices before they are sent for mass production.

From custom tooling for industrial equipment to production parts, rapid tooling supports the industrial manufacturing sector with fast, cost-effective solutions for creating durable components.

Rapid tooling has revolutionized the way industries approach prototype development and low-volume production. With its ability to quickly create molds, tools, and prototypes, it provides a fast and cost-effective solution for many manufacturing processes. Whether you’re in the automotive, aerospace, consumer goods, or medical industry, rapid tooling can streamline your production timelines and reduce costs.

A: Unlike traditional tooling, which can take weeks or months to create, rapid tooling uses advanced manufacturing techniques like 3D printing and CNC machining to create tools in a fraction of the time and cost.

A: While rapid tooling is primarily used for low-volume production, it can be an excellent option for creating tools that will be used in mass production, especially for prototypes and testing.

A: Industries such as automotive, aerospace, consumer goods, medical devices, and industrial manufacturing benefit significantly from rapid tooling due to its speed, cost-effectiveness, and design flexibility.

A: Yes, rapid tooling is ideal for producing complex geometries that are difficult or impossible to create with traditional tooling methods, making it perfect for precision parts.