Views: 0 Author: Site Editor Publish Time: 2025-05-17 Origin: Site

When it comes to manufacturing, the tooling process plays a vital role in determining the efficiency, cost, and speed of production. While conventional tooling has been the backbone of manufacturing for years, rapid tooling has emerged as a revolutionary alternative. But what exactly makes these two types of tooling different, and how do they compare in terms of efficiency, cost, and capabilities?

In this article, we’ll break down the differences between rapid tooling and conventional tooling, looking at the key aspects such as speed, cost, material choice, and application. By the end of this post, you'll understand why more companies are choosing rapid tooling and how it can enhance your production process.

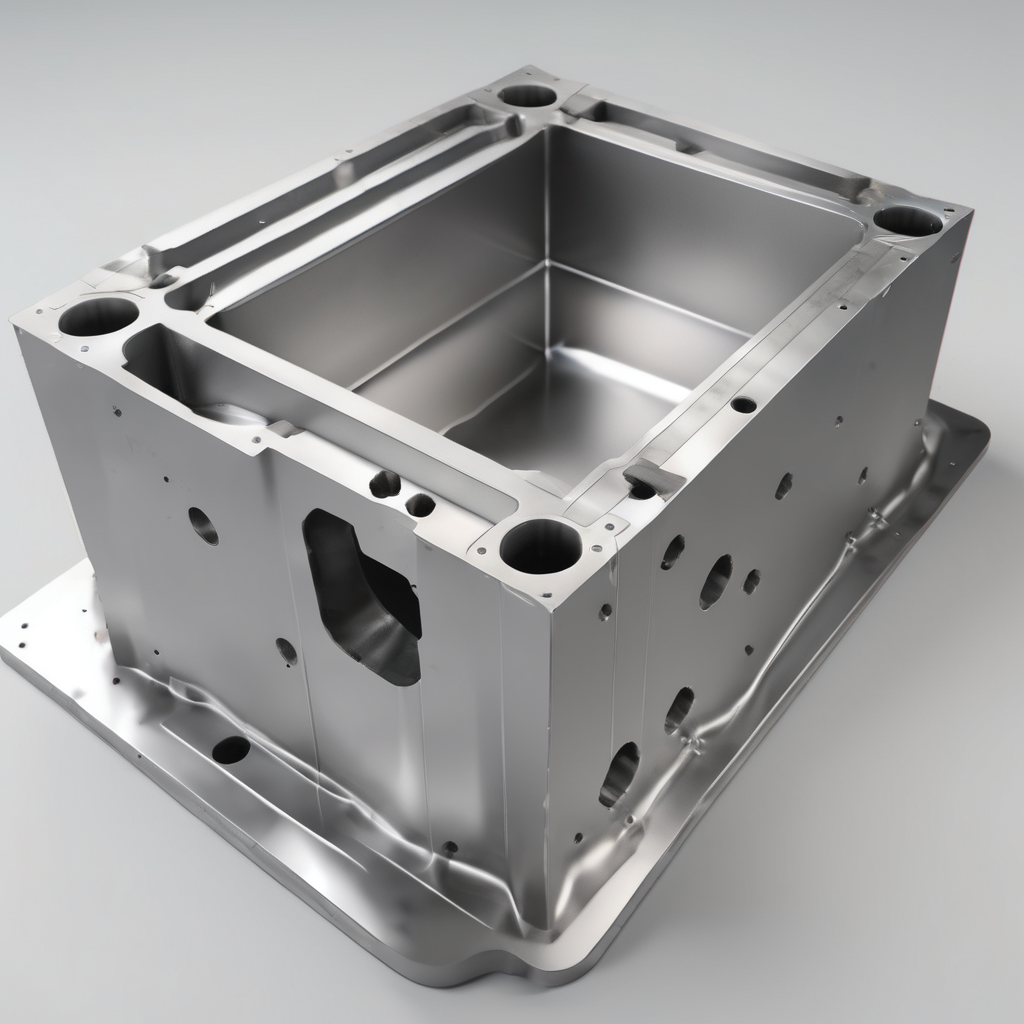

Conventional tooling refers to the traditional methods of producing molds, dies, and other manufacturing tools using techniques such as CNC machining, injection molding, and casting. These methods typically require large investments in machinery, materials, and labor, and they often have long lead times.

Conventional tooling involves several steps:

1. Design and Prototyping: Tooling designs are created using CAD software, and prototypes are tested.

2. Tool Manufacturing: A mold or die is made through machining or casting. This process can be slow and expensive.

3. Production: Once the tool is ready, it is used to produce parts in large quantities. This is often done using traditional injection molding or stamping techniques.

While conventional tooling is suitable for large-scale, high-volume production, it can be time-consuming and expensive, especially during the prototyping and setup phases. The molds or dies created in conventional tooling methods are often made from metal, which adds to material costs, and changes to the design can be challenging and costly to implement.

Rapid tooling refers to the process of quickly manufacturing tooling components, such as molds and dies, using advanced techniques like 3D printing (additive manufacturing), CNC machining, and other rapid prototyping technologies. The key benefit of rapid tooling is its ability to produce tools much faster and at a lower cost compared to conventional tooling methods.

Unlike conventional tooling, rapid tooling relies on digital designs to produce parts or tools, which allows for quick iterations and adjustments. The use of 3D printing or other advanced techniques enables the creation of complex geometries without the need for traditional tooling setups, which can save time and money in the manufacturing process.

1. Digital Design: A 3D model of the part or tool is created using CAD software.

2. Tool Fabrication: The digital design is then converted into a physical tool using 3D printing or CNC machining. These processes can be completed quickly, depending on the complexity of the design.

3. Testing and Iteration: Once the tool is fabricated, it is tested for functionality. If needed, design changes can be quickly implemented, which allows for faster iterations compared to conventional methods.

● Conventional Tooling: Typically, conventional tooling methods can take weeks or even months to complete, especially if a new mold or die needs to be created. This includes the time required for design, material procurement, and setup.

● Rapid Tooling: Rapid tooling significantly reduces lead times. Tools can be created in a matter of days, especially when using 3D printing or CNC machining. This is a major advantage for industries that require fast prototyping or low-volume production.

● Conventional Tooling: Traditional tooling methods can be expensive due to the need for large, complex machinery, skilled labor, and materials like steel or aluminum. The costs can also escalate if design changes are needed after the tooling is created.

● Rapid Tooling: Rapid tooling is generally more cost-effective for low-volume production and prototyping. Because it uses digital files and 3D printing or other additive manufacturing techniques, the material costs and labor requirements are typically lower. Furthermore, the ability to make design adjustments quickly without significant additional costs is a key benefit.

● Conventional Tooling: The materials used in conventional tooling are often limited to metals, which are durable but costly. Additionally, conventional tooling can struggle with producing parts with complex geometries or fine details.

● Rapid Tooling: With rapid tooling, a wider range of materials can be used, including plastics, metals, and composites. Additionally, 3D printing allows for the creation of highly complex geometries and intricate designs that would be difficult or impossible to achieve with conventional methods.

● Conventional Tooling: Best suited for high-volume production runs. Once a tool is made, it can produce thousands or even millions of parts, making it cost-effective for mass production.

● Rapid Tooling: Primarily used for low-volume production or prototyping. While it is possible to produce larger volumes with rapid tooling, the process is more economical for small batches and prototypes where speed and design iteration are more critical than the production scale.

● Conventional Tooling: Making adjustments to conventional tools can be expensive and time-consuming. Once the mold or die is created, any design changes usually require extensive rework.

● Rapid Tooling: Modifications and adjustments are much easier and faster with rapid tooling. Since the process is digitally driven, changes can be made to the design file and reprinted or re-machined with minimal additional cost or time.

By reducing lead times, rapid tooling accelerates the time-to-market for products. Manufacturers can quickly test and iterate designs, helping them respond faster to market demands.

Unlike conventional tooling, which often requires significant upfront investment in equipment and materials, rapid tooling minimizes the initial costs, making it accessible to smaller companies or startups with limited budgets.

The flexibility to make quick adjustments to designs during the tooling process is a major advantage of rapid tooling. This allows businesses to test new concepts and refine their products without the delays associated with conventional tooling.

Because rapid tooling allows for faster adjustments, the risk of delays due to design issues is significantly reduced. This ensures smoother production runs, especially when transitioning from prototype to full-scale manufacturing.

Rapid tooling often results in less waste compared to conventional methods. Traditional tooling can produce significant scrap materials, while 3D printing and additive manufacturing techniques only use the exact material needed, contributing to a more sustainable production process.

● Prototyping and Testing: Ideal for testing design concepts and functionality before full-scale production.

● Low-Volume Production: Suitable for industries requiring limited production runs and quick market entry.

● Custom Tooling: Perfect for creating custom tools or parts tailored to specific needs.

● Mass Production: Best for industries with high-volume production needs, such as automotive or consumer electronics.

● Durable, Long-Lasting Tools: More suitable for applications requiring long-lasting, high-durability tools.

● Cost-Effective for Large Runs: More economical when producing large quantities of parts in a single production cycle.

Both conventional tooling and rapid tooling have their place in modern manufacturing, but the key differences lie in speed, cost, and flexibility. Rapid tooling is an excellent choice for low-volume production, prototyping, and industries that need quick turnaround times. On the other hand, conventional tooling excels in mass production and situations where long-lasting, durable tools are needed.

The growing adoption of rapid tooling offers businesses the opportunity to streamline their processes, reduce costs, and bring products to market faster. By understanding the differences between these two methods, manufacturers can make more informed decisions and optimize their production strategies.

A: The main difference is speed. Rapid tooling is faster, cost-effective, and more flexible, whereas conventional tooling is best for high-volume, mass production and involves longer lead times and higher initial costs.

A: While rapid tooling is primarily used for low-volume production and prototyping, it can also be used for small-scale mass production, especially when speed and flexibility are critical.

A: Industries such as automotive, aerospace, medical devices, and consumer goods benefit the most from rapid tooling due to its fast turnaround times, cost-effectiveness, and design flexibility.

A: Yes, rapid tooling is ideal for creating complex geometries and intricate designs that would be difficult or impossible to achieve with conventional tooling.