Views: 0 Author: Site Editor Publish Time: 2025-05-15 Origin: Site

Reaction Injection Molding (RIM) is one of the most versatile and efficient manufacturing techniques available for producing complex and durable parts. But what exactly makes RIM so suitable for certain applications? In this article, we'll explore the primary uses and advantages of Reaction Injection Molding, focusing on the industries and products that benefit most from this technology.

From automotive parts to consumer goods, RIM has found its place in many fields due to its ability to create strong, lightweight parts with intricate shapes. In this post, we’ll discuss the suitability of RIM for various applications, how it compares to other molding methods, and what industries can achieve with RIM technology.

Reaction Injection Molding (RIM) is a specialized technique where two or more liquid materials are injected into a mold, reacting chemically to form a solid product. This process differs from traditional injection molding in that the materials undergo a chemical reaction inside the mold, which causes them to cure and solidify.

RIM is used to produce parts that require high durability, complex geometries, and lightweight properties. It is particularly useful for producing large parts and for materials that need to maintain structural integrity under harsh conditions.

1. Material Injection: Two liquid components are mixed and injected into the mold.

2. Chemical Reaction: The materials react within the mold, generating heat and curing into a solid part.

3. Demolding: After the reaction is complete, the part is removed from the mold.

One of the most significant areas where RIM is extensively used is in the automotive industry. RIM allows for the production of large, lightweight parts such as bumpers, panels, and body components that can withstand impact and harsh weather conditions.

● Bumpers and Trim: RIM’s ability to create large, impact-resistant parts makes it ideal for bumpers and other exterior components.

● Interior Panels: RIM can be used for dashboard panels, door panels, and other interior car parts that require precision and durability.

RIM is also widely used in the production of consumer products that require both strength and aesthetics. The ability to create parts with complex shapes makes it ideal for products such as furniture, electronics, and household items.

● Furniture: Lightweight yet strong parts, such as armrests, seat backs, and table bases, are commonly made using RIM.

● Appliance Parts: RIM is used to manufacture parts like housing enclosures, which need to be durable and able to support electrical components.

The industrial sector benefits from RIM’s ability to produce durable components for machinery and equipment. These parts need to withstand heavy wear and tear, and RIM's versatility allows for the creation of custom-designed parts with unique shapes and features.

● Housings and Enclosures: RIM is perfect for creating protective enclosures that shield sensitive electronic or mechanical components.

● Gaskets and Seals: The chemical reaction in RIM ensures that parts are tight-fitting, which is essential for industrial machinery.

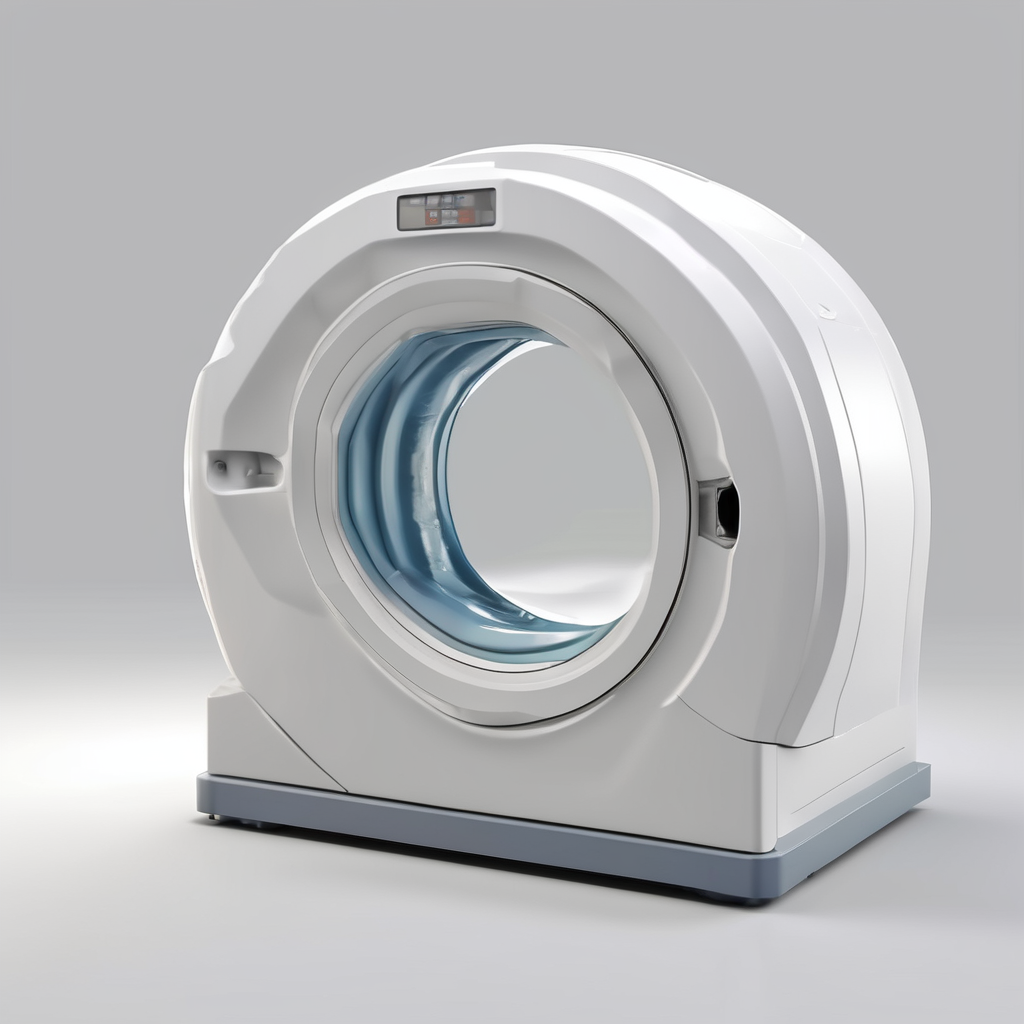

RIM is also suitable for the medical industry, where precise, strong, and lightweight parts are often needed. The process allows for the production of custom parts that are both durable and cost-effective.

● Medical Equipment Casings: Durable, lightweight casings for medical devices are produced using RIM, ensuring protection for sensitive internal components.

● Orthopedic Devices: RIM allows for the production of custom-fitted orthopedic parts that require a high degree of precision and strength.

The sports industry relies heavily on Reaction Injection Molding to produce durable, high-performance equipment. From helmets to padding, RIM helps create products that can withstand rigorous use while remaining lightweight.

● Helmets: RIM’s ability to produce impact-resistant materials makes it perfect for creating protective gear, such as helmets for various sports.

● Pads and Protective Gear: RIM is also used to make elbow pads, knee pads, and other protective gear designed for athletes.

While the initial investment in RIM equipment can be high, the long-term cost savings make it an attractive option for manufacturers. The ability to produce large, complex parts without requiring extensive labor or tooling changes results in lower overall production costs.

RIM allows for the creation of intricate shapes and designs that would be difficult or impossible to achieve with other molding methods. This makes it an excellent choice for industries where custom parts are required.

The chemical reactions involved in RIM create strong, durable parts that can withstand harsh environmental conditions, heavy use, and physical stress. This is particularly important in industries like automotive and industrial manufacturing, where part longevity is critical.

One of the key benefits of RIM is the ability to create lightweight parts without sacrificing strength or durability. This is especially important in industries like automotive manufacturing, where reducing weight can improve fuel efficiency and performance.

While traditional injection molding is faster and more cost-effective for producing simple parts, RIM excels when it comes to creating complex, large, and durable parts. RIM’s ability to produce parts with unique chemical properties gives it an edge for applications that require impact resistance, lightweight strength, and design flexibility.

Compression molding is another popular method for producing parts, especially in the automotive and aerospace industries. However, RIM has the advantage when it comes to producing parts with more complex shapes and finer details. The material properties in RIM can also provide superior strength and durability, making it more suitable for demanding applications.

To achieve the best results with RIM, manufacturers should focus on optimizing several key factors:

● Material Selection: Choosing the right materials ensures the final product has the necessary properties such as strength, flexibility, and resistance to wear and tear.

● Mold Design: Efficient mold design can speed up the process and reduce costs. It's important to consider factors like venting, mold cooling, and material flow.

● Temperature Control: Proper temperature management during the chemical reaction is crucial for ensuring high-quality, defect-free products.

Reaction Injection Molding is an incredibly versatile and efficient process that is suitable for a wide range of industries, from automotive and medical devices to consumer goods and industrial components. Its ability to produce complex, durable, and lightweight parts at a relatively low cost makes it an ideal choice for many manufacturing needs.

A: Industries such as automotive, medical devices, consumer goods, sports equipment, and industrial manufacturing benefit greatly from Reaction Injection Molding due to its ability to create durable, complex parts at a cost-effective rate.

A: Yes, RIM is especially well-suited for producing large parts, such as bumpers, panels, and housing components, while maintaining strength and durability.

A: While the initial setup for RIM may be higher, it offers significant cost savings in the long term due to the reduced need for labor, tooling, and material waste.

A: The main advantages of RIM include cost-effectiveness, design flexibility, durability, strength, and the ability to produce lightweight yet robust parts.